Electroplating Tank Liners

Electroplating Tank Liners

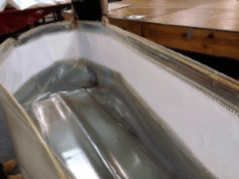

Perfect Fit Tank Liners manufactures flexible, custom-made, drop-in tank liners for all electroplating and anodizing operations. Flexible drop-in tank liners are comparatively inexpensive and can easily be installed by your own shop personnel. In addition, drop-in tank liners can be made and shipped to you quickly, reducing down time and loss of production. They are adaptable to nearly all sizes and shapes of tanks and are resistant to a wide range of chemicals.

Storage or Processing Tanks

- Steel – mild or stainless

- Wood – stave or plywood

- Concrete – block or poured

- Plastic – rigid PVC or Polypropylene

- Fiberglass

*tank must be structurally sound

THE PROBLEM

– New tank is too costly

– Leaky Tank – from cracks or corrosion

– Tank contaminates solution

– Old lining contaminates solution

– Bonded-in lining is hardening and cracking

– Solution chemically attacks tank

– Other lining methods too costly or time-consuming to install

THE ANSWER: Flexible PVC Tank Liners

– Quick easy installation with minimal down time and loss of production

– Use of your own personnel rather than expensive outside contractors in most cases

– Inexpensive compared to other alternatives

– Custom made to tank dimensions for proper fit

– Elimination of sandblasting and bonding of liner to tank

– No other expensive tank preparation – just smooth down sharp projections

– Liner will expand and contract with temperature changes and tank movement

– Long lasting superior material formulations for widest range of chemical resistance

– Easy to repair

Accessories and Features

Wide variety of optional features available to facilitate particular tanks and special situations. These include:

– Hem and rope or grommets and rope around top perimeter of liner or unique stainless steel clips to easily secure liner in place

– Double thickness or floating bottoms for extra protection

– Skirt (double thickness) at liquid / air interface in chrome plating applications

– Sumps and overflows built in

– Outlet tubes (attached or seperate) or compression fittings for plumbing through liners

– Special built-in hold downs for attachment of rigid PVC to liner bottom for protection from falling parts

Tank Liner Materials

Only the highest quality pinhole free virgin materials are used in a variety of thicknesses and formulations to fit most any application. Materials are one ply and homogeneous, not multiple plys or laminated.

Some standard thicknesses are:

187 mil (.187″, 3/16″) 30 mil (.030″, 1/32″)

125 mil (.125″ 1/8″) 20 mil (.020″)

93 mil (.093″, 3/32″) 16 mil (.016″)

60 mil (.060″, 1/16″) 12 mil (.012″)

40 mil (.040″) 8 mil (.008″)

For information regarding specific chemical resistance contact CTO Enterprises or request chemical resistance chart.

PTFE Skirts

CTO Enterprises manufactures flexible, custom made, PTFE skirts attached to drop-in tank liners for all electroplating and anodizing operations.

In addition, drop-in tank liners with PTFE Skirts can be made and shipped to you quickly, reducing down time and loss of production. They are adaptable to nearly all sizes and shapes of tanks and are resistant to a wide range of chemicals.

Tanks utilizing a Hard Chrome application can benefit from a PTFE Skirt by reducing the affects of the fumes.

Request A Quote

Interested with any of our products?

Website Accessibility

CTO Enterprises is committed to facilitating the accessibility and usability of its Website, www.perfectfittankliners.com, for all people with disabilities. If you use assistive technology (such as a Braille reader, a screen reader, or TTY) and the format of any material on this website interferes with your ability to access information, please contact us. If you do encounter an accessibility issue, please be sure to specify the Web page in your email, and we will make all reasonable efforts to make the page accessible for you. Users who need accessibility assistance can also contact us by phone at 1-708-479-5501 (voice). Our Website will be reviewed, tested, and improved on an ongoing basis.