Clean water storage is essential for safe operations and long equipment life. When tanks are maintained properly, they deliver reliable water for drinking, fire protection, industrial use, and countless other applications. Algae, however, can upset that balance. Even small amounts of algae can change how water tastes and smells, create more maintenance work, and make people doubt its quality. By knowing what algae need to grow and how to stop those conditions, facility managers can keep tanks working well, safe to use, and up to standard.

Clean water storage is essential for safe operations and long equipment life. When tanks are maintained properly, they deliver reliable water for drinking, fire protection, industrial use, and countless other applications. Algae, however, can upset that balance. Even small amounts of algae can change how water tastes and smells, create more maintenance work, and make people doubt its quality. By knowing what algae need to grow and how to stop those conditions, facility managers can keep tanks working well, safe to use, and up to standard.

This guide looks at why algae shows up in water tanks, simple ways to stop it, and the steps that keep tanks running well. It also explains how using water tank liners can prevent algae and protect the tank at the same time. For facility managers who want to strengthen their maintenance plans, Perfect Fit Tank Liners provides custom liners made with proven materials, precise fit, and long-term reliability. This investment improves water quality and lowers operating costs.

The Problem With Algae Growing Inside Your Water Tank

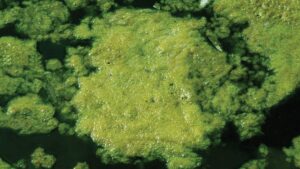

Algae can create more than a green tint. It can change the taste and odor of water, place extra load on filters, and form slimy layers on tank walls. This reduces confidence in the supply and increases maintenance.

Some forms of algae may also produce toxins. While uncommon, this can impact drinking water systems, process lines, and fire tanks. Growth in storage tanks is also linked to higher chlorine demand, meaning disinfectant is used up more quickly. Treating algae as a maintenance priority protects water quality and helps the tank operate the way it was designed.

Why Is Algae Growing in My Water Tank?

Algae thrive when light, still water, and nutrients are present. If sunlight reaches the water through translucent walls, open hatches, or poorly sealed lids, algae can multiply quickly. Water that is not moving warms up, layers form, and chlorine or other disinfectant levels fall. These conditions give spores space to settle and grow.

Nutrients also play a part. Dust, pollen, insects, and debris can enter through vents and openings if screens are missing or loose. Sediment at the bottom of the tank and rust from older steel provide more material for algae to feed on. Warm conditions, especially in summer, accelerate the process. Keeping tanks shaded, circulated, and sealed is the best way to prevent algae-friendly conditions.

How Custom Tank Liners Stop Algae Before It Starts

- Custom liners act as a clean inner surface for your tank. They separate the water from rough concrete or corroded steel and set a new, smooth surface inside.

- Block light: Opaque liners stop sunlight from reaching the water, removing the energy algae need to grow. This is one reason water tank liners are widely used in outdoor tanks.

- Create a smooth surface: Concrete pores and metal pits give algae places to attach. Liners provide a smooth, food-grade surface that makes cleaning easier and prevents buildup.

- Seal cracks and pores: A liner covers seams, corners, and joints, reducing hidden areas where water might sit still.

- Protect disinfectant performance: By isolating water from reactive walls, liners reduce chlorine loss. This means disinfectant lasts longer and works more effectively.

- Custom fit: A well-designed liner eliminates folds and pockets that could hold water. This is where custom tank liners show their value.

Perfect Fit Tank Liners specializes in precision fabrication, ensuring every liner fits properly and provides a long-term defense against algae.

The Importance of Routine Water Tank Inspections

Routine inspections keep water clean and help tanks last longer. Industry standards recommend scheduled inspections of internal and external conditions. This can uncover signs of algae, corrosion, or sediment buildup. External water tank checks should be done monthly, taking a look at hatches, vents, seals, and screens.

Quarterly water testing helps track disinfectant levels, pH, and temperature, giving early warning if algae-friendly conditions are forming. Annual or biannual internal inspections, carried out with cameras, divers, or full drain-downs, allow facility managers to identify biofilm, folds in liners, or structural changes before they lead to larger issues.

Inspections also confirm the performance of any preventive measures already in place. When water tank liners are installed, inspections ensure seams remain flat, penetrations are sealed, and liner surfaces are clean and intact. A small repair identified during inspection can be handled quickly, keeping the tank in service with minimal disruption. Documenting inspections provides a valuable record for future planning, helps support regulatory compliance, and reduces the risk of costly corrective work. With inspections built into a consistent schedule, tanks remain reliable assets rather than unexpected liabilities.

Water Tank Maintenance Tips

Good practices reduce algae and make tanks easier to manage:

- Keep light out: Paint translucent shells, use opaque lids, and cover skylights. Blocking light removes the main driver of algae growth. Pairing these steps with water tank liners gives you even stronger control.

- Keep debris out: Screen vents and overflows. Seal gaps and keep nearby areas clean to reduce nutrient entry.

- Keep water moving: Install a recirculation pump or schedule periodic drawdowns to prevent stagnation.

- Clean on a schedule: Drain, rinse, and disinfect before buildup occurs. Crews often note faster cleaning when liners are installed.

- Use disinfectant carefully: Hold a modest chlorine residual if allowed. Test often and adjust to meet standards.

- Document checks: Keep a log of inspections, water tests, and cleanings. Records help track trends and guide improvements.

These practices protect water quality and support the long life of both the tank and its liner. For facilities managing multiple tanks, they also standardize maintenance and improve efficiency across the board.

Extra Benefits of Water Tank Liners

The benefits of liners extend beyond algae prevention. By separating water from tank walls, liners reduce corrosion, stop leaching, and often extend tank service life. They can also seal fine cracks and seams, cutting water loss and preventing intrusion. On the water quality side, liners remove contact with rust or concrete, providing a clean, food-grade surface that keeps water clear and reduces strain on equipment.

Liners also improve maintenance efficiency. Smooth walls clean quickly, with fewer places for biofilm to collect, which shortens downtime. Many liner materials resist a range of chemicals, so they perform well with disinfectants and even certain industrial liquids. When combined, these benefits show why water tank liners are a practical investment: they protect assets, support water quality, and reduce long-term operating costs.

Buy High-Quality Water Tank Liners at Perfect Fit Tank Liners

When adding a liner, choose a partner that builds to your tank, not around it. Perfect Fit Tank Liners has specialized in custom liners since 1978. Their team uses high-quality, potable-safe materials and precision welding for seams and corners that sit flat and secure. This attention to detail prevents folds and pockets where algae could settle and makes cleaning easier.

The Perfect Fit process starts with measurements and operating details. From there, they design and fabricate a liner that drops in cleanly and performs from day one. Many facilities rely on their liners to upgrade water quality, extend tank life, and simplify maintenance. When you need reliable water tank liners or express service, Perfect Fit provides the expertise and quality you can trust.

Website Accessibility

CTO Enterprises is committed to facilitating the accessibility and usability of its Website, www.perfectfittankliners.com, for all people with disabilities. If you use assistive technology (such as a Braille reader, a screen reader, or TTY) and the format of any material on this website interferes with your ability to access information, please contact us. If you do encounter an accessibility issue, please be sure to specify the Web page in your email, and we will make all reasonable efforts to make the page accessible for you. Users who need accessibility assistance can also contact us by phone at 1-708-479-5501 (voice). Our Website will be reviewed, tested, and improved on an ongoing basis.